ISM chart and excerpts below by permission from the Institute for Supply Management® ISM®

ISM chart and excerpts below by permission from the Institute for Supply Management® ISM®

Please consider the November 2024 Manufacturing ISM® Report On Business®

emphasis in bold by ISM, italics mine.

The report was issued today by Timothy R. Fiore, CPSM, C.P.M., Chair of the Institute for Supply Management® (ISM®) Manufacturing Business Survey Committee.

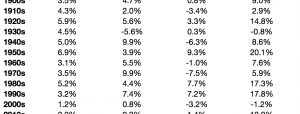

“U.S. manufacturing activity contracted again in November, but at a slower rate compared to last month. Demand continues to be weak but may be moderating, output declined again, and inputs stayed accommodative. Positive signs for demand include the (1) New Orders Index returning to expansion territory, (2) New Export Orders Index increasing moderately (up 3.2 percentage points but still in contraction territory), (3) Backlog of Orders Index dipping further into strong contraction territory, and (4) Customers’ Inventories Index indicating levels were only marginally above ‘too low.’ (For more, see the Customers’ Inventories Index summary section.) Output (measured by the Production and Employment indexes) continued in contraction: Employment shrunk, but at a much slower rate, and production took a small step in the right direction. Foundational industries like Chemical Products and Fabricated Metal Products (that provide products and components across the manufacturing sector) continued to show weakness, indicating that recovery may still be two to three months away. Inputs — defined as supplier deliveries, inventories, prices and imports — generally continued to accommodate future demand growth, with inventories improving and suppliers continuing to improve delivery performance.

“Demand remains weak, as companies prepare plans for 2025 with the benefit of the election cycle ending. Production execution eased in November, consistent with demand sluggishness and weak backlogs. Suppliers continue to have capacity, with lead times improving but some product shortages reappearing. Sixty-six percent of manufacturing gross domestic product (GDP) contracted in November, up from 63 percent in October.

Respondent Comments

Negative and Positive CommentsNegative Comments: 1, 2, 3, 5, 6, 9Positive Comments: 4, 7, 8, 10

Scrambling to Avoid TariffsPlease note the improvement in inventories from 42.6 to 48.1. A scramble to get ahead of tariffs is underway.Number 9 is interesting: “Late to the game, we are now working on our buying plan in light of potential increased tariffs on imports from China. Cost and capacity of U.S. manufacturing is a concern; a lack of relationship with alternate low-cost international manufacturers is another.” Businesses late to the game may have thought Kamala Harris would win. Regardless, in light of Trump tariffs, all importers are scrambling to locate “alternate low-cost” suppliers.These actions will shift imports, not reduce them. And shifting supply chains, in and of itself, increases costs.

Electronic Products

Meanwhile, the backlog index further contracted to 41.8 as shown in the lead chart.Perhaps points 4 and 8 are outliers, but it could be something with chips or AI, or alternatively point number 9 once again.

ConclusionThe manufacturing index improved slightly in that it is less negative, but the only strength is suspect.Some manufactures are scrambling to find alternative suppliers. Others are stockpiling made in China to avoid tariffs.

Trumpian Tariff Blast ComingNothing good will come from a Trumpian tariff blast.For discussion, please see Trump’s Obvious Bluff Over BRICS Currency Proves He Is Clueless on TradeTrump’s big problem is that he does not understand what’s driving trade. Tariffs won’t fix it.For discussion, please see the above link.More By This Author:Trump’s Obvious Bluff Over BRICS Currency Proves He Is Clueless On TradeContinued Unemployment Claims Increase Another 9,000, It’s Recession LookingAir Cargo Flights From China Jumps 73 Percent In Mad Rush To Avoid Trump’s Tariffs