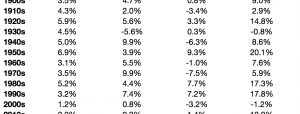

The MITI V is the latest acronym to emerge from the wordsmiths at Deloitte’s. Malaysia, India, Thailand, Indonesia and Vietnam. All these countries have a competitive advantage over China in the manufacture of labour intensive commodity type products like apparel, toys, textiles and basic consumer electronics. According to Deloitte’s 2016 Global Manufacturing Competitiveness Index they are either among, or destined to join, the top 15 most competitive countries in the world for manufacturing, by the end of the decade. Here is the Deliotte 2016 ranking:-

Source: Deliotte

The difficulty with grouping disparate countries together is that their differences are coalesced. Malaysia and Thailand are likely to excel in high to medium technology industries, their administrations are cognizant of the advantages of international trade. India, whilst it has enormous potential, both as an exporter and as a manufacturer for its vast domestic market, has, until recently, been less favourably disposed towards international trade and investment. Vietnam continues to benefit from its proximity to China. Indonesia, by contrast, has struggled with endemic corruption: its economy is decentralised and this vast country has major infrastructure challenges.

The table below is sorted by average earnings:-

Source: World Bank, Trading Economics

India and Vietnam look well placed to become the low-cost manufacturer of choice (though there are other contenders such as Bangladesh which should not be forgotten when considering comparative advantage).

Another factor to bear in mind is the inexorable march of technology. Bill Gates recently floated the idea of a Robot Tax, it met with condemnation in many quarters – Mises Institute – Bill Gates’s Robot Tax Is a Terrible Idea – examines the issue. The mere fact that a Robot Tax is being contemplated, points to the greatest single challenge to low-cost producers of goods, namely automation. Deliotte’s does not see this aspect of innovation displacing the low-cost manufacturing countries over the next few years, but it is important not to forget this factor in one’s assessment.

Before looking at the relative merits of each market from an investment perspective, here is what Deliotte’s describe as the opportunities and challenges facing each of these Asian Tigers:-

Malaysia

…has a low cost base with workers earning a quarter of what their counterparts earn in neighboring Singapore. The country also remains strongly focused on assembly, testing, design, and development involved in component parts and systems production, making it well suited to support high-tech sectors.

…is challenged by a talent shortage, political unrest, and comparatively low productivity.

India

Sixty-two percent of global manufacturing executives’ surveyed rank India as highly competitive on cost, closely mirroring China’s performance on this metric.

…highly skilled workforce and a particularly rich pool of English speaking scientists, researchers, and engineers which makes it well-suited to support high-tech sectors. India’s government also offers support in the form of initiatives and funding that focus on attracting manufacturing investments.

…challenged by poor infrastructure and a governance model that is slow to react

…As 43 percent of its US$174 billion in manufacturing exports require high-skill and technological intensity, India may have a strong incentive to solve its regulatory and bureaucratic challenges if it is to strengthen its candidacy as an alternative to China.

Thailand

When it comes to manufacturing exports (US$167 billion in 2014), Thailand stands slightly below India, but exceeds Malaysia, Vietnam, and Indonesia. This output is driven largely by the nation’s skilled workforce and high labor productivity, supported by a 90 percent national literacy rate, and approximately 100,000 engineering, technology, and science graduates every year.

…highly skilled and productive workforce creates relatively high labor costs at US$2.78 per hour in 2013.

…remains attractive to manufacturing companies, offering a lower corporate tax rate (20 percent) than Vietnam, India, Malaysia or Indonesia. Already well established with a booming automotive industry, Thailand may provide an option for manufacturers willing to navigate the political uncertainty that persists in the region.

Indonesia

Manufacturing labor costs in Indonesia are less than one-fifth of those in China.

…The island nation’s overall 10-year growth in productivity (50 percent) exceeds that of Thailand, Malaysia, and Vietnam,

…manufacturing GDP represents a significant portion of its overall GDP and with such a strong manufacturing focus, particularly in electronics, coupled with the sheer size of its population, Indonesia remains high on the list of alternatives for manufacturers looking to shift production capacity away from China in the future.

Vietnam

…comparatively low overall labor costs.

…has raised its overall productivity over the last 10 years, growing 49 percent during the period, outpacing other nations like Thailand and Malaysia. Such productivity has prompted manufacturers to construct billion-dollar manufacturing complexes in the country.