SemiAnalysis has a scathing report on critical mistakes made by Intel (INTC). Let’s investigate.

Please consider Intel on the Brink of Death | Culture Rot, Product Focus Flawed, Foundry Must Survive

Intel’s board is incompetent and its horrible decisions over the decades are going to push it towards death. The decision to fire Pat Gelsinger, put in charge a CFO + career sales and marketing leader, and cut spending on fabs in favor of a renewed focus on x86 is an example of the incompetence that will end Intel. Fabricated Knowledge wrote The Death of Intel: When Boards Fail recently explaining how board issues around leadership and planning have failed the company. Simply put, the Intel board has escaped blame for over a decade of failures. This decade of failure culminates in the ultimate mistake: dismissing CEO Pat Gelsinger.

Upon closer inspection, these failures are no surprise. 7 of 11 members have no relevant semiconductor experience. Two more are accomplished in the field but as academics, not industry players. They have no experience making hard decisions, understanding critical business inflections, and are not qualified for what’s at stake. The only member with a strong and relevant CV, Stacy J. Smith, joined just this year as a replacement for Lip-Bu Tan.

Intel’s Failures

The problems at Intel began with the 10nm node (arguably 14nm). In 2016, TSMC and Intel planned to introduce their 10nm processes into volume production. While TSMC executed on schedule with a lower performing node, Intel pushed an aggressive shrink requiring quadruple patterning, novel Cobalt interconnects, and contact over the active gate. The yield was bad, and the node took three years to fix. By the time Intel shipped 10nm products in volume, TSMC had sold more than half a million N7 wafers and was sampling N5.

Competitors like AMD had the advantage of TSMC’s fabrication and in many cases better chip designs/architectures. Datacenter market share began to slip, and Intel’s business issues only snowballed.

Culture – Rotten to the Core

The story of Intel’s cultural rot goes back to Paul Otellini. Paul and Pat Gelsinger were the front runners for the CEO position. This is the classic leadership choice of business bro versus technologist. The result was that Intel chose its first non-engineer CEO.

Paul was ultimately chosen due to his ruthless anti-competitive business decisions that locked AMD out of the CPU market and cemented Intel’s role as a monopoly for more than a decade. Paul instituted a policy that involved paying various OEMs and system integrators not to use AMD, which choked out AMD’s revenue, R&D, and fab investments. Dell alone was paid ~$4.3 billion, and this was the only reason Dell was profitable during this period. Intel and the EU are still fighting out this anti-competitive behavior in courts to this day.

Brian Krzanich was a disaster as CEO. He presided over the 10nm debacle. This mismanagement of the fabs is the single greatest issue the company faced, because that is the core of Intel. Despite this, Krzanich was only fired when an illicit workplace relationship came to light.

Not to be outdone, the 2018 board iteration replaced Krzanich with the first truly non-technical CEO in Intel’s history: Bob Swan. Technically, Paul Otellini was the first non-engineer to lead Intel, but he spent more than 30 years with the company, including his time as a technical advisor to the legendary Andy Grove and leading the microprocessor division.

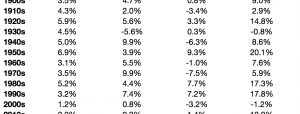

Swan was a professional CFO – Intel was his 10th CFO role – and so process engineering took a backseat to financial engineering. Swan’s Intel spent as much on stock buybacks as it did capital expenditures on fabs over his tenure: more than $36 billion towards buybacks versus $38 billion in Capex. This was malpractice in a capital-intensive industry when the company was bleeding market share and more than two nodes behind its chief rival.

Brian Krzanich, Bob Swan, and Intel’s board cut not only Capex, but also technical talent, in droves. From 2013 to 2020, 4 out of 7 years had shrinking headcount all while the business lost its technical leadership and had fantastic profitability.

There is No Moat in x86 and the Product Group

Intel’s glory days were when they had superior process technology combined with their x86 moat. The x86 moat was also twofold: Intel had a moat in x86, and x86 had a moat in computing. Today, neither of those moats hold.

Before the smartphone era, x86 was the dominant instruction set within general-purpose CPUs. Almost every PC and server was guaranteed to have an x86-based CPU as the software was written to be compatible with the x86 instruction set. This was propagated by the “Wintel” (Windows and Intel) alliance, where Windows was the dominant Operating System that ran exclusively on x86. Software developers would rationally focus their efforts on developing software for the largest user base: Windows, and that meant making software for x86. This was a classic ecosystem: customers would want Windows PCs because of the larger suite of software options, and to use Windows meant buying an x86-based CPU.

Most of those x86 CPUs were Intel CPUs. While AMD also had the IP rights to design x86-based CPUs, AMD was for a long time tied to its own fabs (now spun off as Global Foundries) with inferior process technology to Intel’s, making it uncompetitive. Ironically, this is Intel’s position today.

Competition is Coming Even for x86 Client CPUs

This began the fading relevance of Windows and Intel, replaced by the Apple and Arm era. This partnership has encroached on Intel Product Group’s core: Apple took the knowledge and experience from designing APs with their A-series iPhone SoCs and parlayed that into the hugely successful Arm-based M-series SoCs for their client notebooks and desktops in 2020. Fifteen years after succumbing to the dominance of x86 over IBM PowerPC, Apple ended its Intel partnership.

This transition was only made possible with a tremendous effort to port software written for x86 to Arm. The key piece was the Rosetta 2 emulator, which recompiled apps at install to work with Apple silicon, enabling a seamless transition. The Apple M1 unlocked substantial performance gains with various accelerator engines not offered by Intel along with considerable boosts in battery life. It was a hit.

Trump and a Chip CzarSemiAnalysis says it’s crucial to save Intel’s foundry on grounds of national security.

Customers want to de-risk their TSMC/Taiwan exposure the same way the national security community does.

Intel Foundry should be laser-focused on 1) a competitive process technology and 2) making design switch over from TSMC as cheap and easy as possible. The former is on track, but it is not clear what the latter is. A split from the Intel parent would reduce distractions and increase focus. Government support on national security grounds is necessary. Intel Foundry is the single best hedge America has against a Chinese-sponsored coup or invasion of Taiwan.

But note that Intel selling Intel Foundry will not work without a significant capitalization to the tune of ~$50B injected into Intel Foundry. AMD tried to spin off the fabs, and it was disastrous. Mubadala purchased the fabs from AMD and created GlobalFoundries. They then proceeded to lose $22.4 billion over the next decade.

While the Trump administration is probably allergic to anything that looks like “corporate welfare,” many key officials are national security hawks who recognize the importance of having advanced logic manufacturing capability on-shore. A standalone Intel Foundry that is capitalized and with long term manufacturing agreements from 2 of the largest semiconductor companies in the US is much easier for the government to support, both in dollar amounts and politically.

Intel Foundry won’t be laden with Intel’s lagging product team, Mobileye, or Altera. Intel Foundry will have one clear function, and it’s vital to national security and the future of America and the West.

Who should lead the charge here? Maybe a “Chip Czar” charged with restoring American logic prowess. We know someone with a great CV who has just become freed up for new opportunities…

Priorities, PrioritiesThere is much more in the lengthy article for inquiring minds to investigate. It does take a subscription to read some of it, but there is plenty to see without subscription.Chips are a genuine matter of national security, not autos, not underwear, not most of the things Trump is pissing and moaning on tariffs over.But we are off to a horrid start.

Intel Announces 15,000 Job Cuts, 15 Percent of its WorkforceOn August 1, 2024 I noted Intel Announces 15,000 Job Cuts, 15 Percent of its Workforce

Intel received $8.5 billion in Biden administration grants (Inflation Reduction Act) but announces massive layoffs and halts dividends due to a decline in revenue.

Intel’s Money Woes Throw Biden Team’s Chip Strategy Into TurmoilOn September 4, Bloomberg reported Intel’s Money Woes Throw Biden Team’s Chip Strategy Into Turmoil

The Biden-Harris administration’s big bet on Intel Corp. to lead a US chipmaking renaissance is in grave trouble as a result of the company’s mounting financial struggles, creating a potentially damaging setback for the country’s most ambitious industrial policy in decades.

TSMC Arizona Production Remains on ScheduleOn September 9, 2024 TechPowerUp reported TSMC Arizona Achieves Yield Parity with Taiwanese Facilities, Production Remains on Schedule

TSMC has reportedly managed to produce yields at its Arizona facility that are on par with yields back home in Taiwan, making its expansion efforts successful. According to Bloomberg, TSMC did a trial production, a multi-month effort, to produce N4 node wafers with low defect rates. With wafers now in TSMC’s labs for testing, it is reported that Arizona facility yields have achieved parity with their Taiwanese facilities back home. This indicates that TSMC’s efforts to expand in the US are so far considered a success, as advanced chipmaking is a very complex process that is only done by a few makers and in very few locations. With TSMC expanding in the US now and proving that its technology can work on US soil, the company has a green light to start volume production in the first half of 2025.

However, this is only the beginning of TSMC’s Arizona expansion. The Taiwanese giant plans to have a second fab operational by 2028 and produce 2 nm and 3 nm chips in the state. Additionally, there will be a third facility for 2 nm and more advanced nodes in Phoenix, bringing the total value of TSMC’s US expansion efforts to $65 billion, with $6.6 billion from the CHIPS Act grants and $5 billion in loans from the US government. If upcoming fabs follow the lead of the first facility, US-based production needs will possibly be satisfied.

Trump Accuses Taiwan of Stealing U.S. Chip Industry, Threatens TariffsOn October 29, I noted Trump Accuses Taiwan of Stealing U.S. Chip Industry, Threatens Tariffs

Trump also suggested foreign companies shouldn’t be able to enter the U.S. and use government money. “That chip deal is so bad,” he said. “We put up billions of dollars for rich companies to come in and borrow the money and build chip companies here. They’re not going to give us the good companies anyway.”

The claim seems absurd given TSMC is investing in technology in the US.Trump does not like any deal he didn’t negotiate. Heck, he does not even like the USMCA (NAFTA rewrite) that he did negotiate.Getting TSMC to build a factory in the US was one of the best things, perhaps the only thing, good to come out of the Chips act.More By This Author:A Mass Exodus Of Big Banks From The Net-Zero Bank Climate Alliance

ISM Manufacturing Contracts 9th Month And The 25th Time In Last 26 Months

Five Funding And Legal Obstacles To Trump’s Immigration Plans